In 2020, Viking Pump joined forces with a fellow IDEX business unit Wright Flow Technologies and began selling a leading hygienic line of products produced by Wright Flow Technologies. This broad line combines local engineering and global distribution with 40 plus years of market expertise and solutions for hygienic applications. The expansion of offering rotary lobe, circumferential piston and centrifugal pumps rounds out a range of product solutions to meet customer’s needs.

Site-specific problem-solving

Further testing, upon request (magnetic particle, dye penetrant, traceability, and positive material identification)

Quality control of all finished products

Full product testing (performance, hydro, pneumatic, NPSHr, sound, and vibration)

Liquid sample analysis (rheology testing and elastomeric compatibility)

Common applications for hygienic pumps includes but are not limited to:

- Beverage

- Bio-Pharmaceutical

- Chemical and Industry

- Dairy

- Food

- Personal Care

Pumps are available EHEDG and 3A certified, guaranteeing our pumps meet the highest levels of hygienic performance for all your activities wherex maximum sanitary conditions are of foremost importance.

Range of pumps to suit many industries

Revolution

CLEANABILITY

- Efficient CIP (Clean In Place) ability is standard for all Revolution pumps

- Self draining pump head from innovative cusps & cusp reliefs

- Innovative seal design with no dead zones & a dynamic leak path

- No dead zones on front cover

EASE OF MAINTENANCE

- Fast, front loading seal changes while pump is still in line

- Front access shimming for setting rotor clearance significantly reduces maintenance time

- Convenient preventive maintenance parts kits available

PERFORMANCE

- Improved volumetric efficiency in low & high viscosity applications

- Up to 15% better flow performance than competitors’ CIP configuration with CPP version

- Gentle handling of solids & shear sensitive products

- Long-life durability from heavy duty shafts, bearings & helical gears

- Less overhung load

TRA10 Series

CLEANABILITY

- Easy disassembly for easy COP (Clean Out of Place)

- Designed to 3A standards

PERFORMANCE

- Efficient handling for low & high viscosity applications

- Exclusive, non-galling WFT 808® alloy rotors standard; permits running at tighter clearances

- High strength 17-4 PH single piece shaft standard on 0300 and larger

- Helical gears, improving load carrying capabilities

EASE OF MAINTENANCE

- Drop-in-place with TRA®20 & comparable manufacturer models

- Interchangeable service parts with comparable manufacturer models

- Easy disassembly

TRA20 Series

CLEANABILITY

- CIP (Clean In Place) design optional

- Free draining cover with flat body profile option

- Sealed shaft with o-ring on rotor & rotor nut

PERFORMANCE

- Efficient handling for low & high viscosity applications

- Exclusive, non-galling WFT 808® alloy rotors standard; permits running at tighter clearances

- High strength17-4 PH single piece shaft standard

- Improved load carrying capabilities

EASE OF MAINTENANCE

- Drop-in-place with TRA®10 & comparable manufacturer models

- Interchangeable service parts with comparable manufacturer models

- Stainless steel bearing retainers standard, prevent rusting

Sterilobe

CLEANABILITY

- Cover joint profile improves hygienic characteristics & self-draining capabilities

- Clean & corrosion resistant stainless gear cover & powder coated bearing housing

EASE OF MAINTENANCE

- Front loading seals can be changed while the pump is still in-line

- Seal positioned for optimal lubrication, maximizing seal life

- Hassle free gearbox maintenance with sealed for life bearings

PERFORMANCE

- Standard bi-wing rotors offer application flexibility & good solids handling capabilities

- Multi-lobe rotors reduce shear & pulsation effect; ideal for sensitive media

- Innovative cusps with reliefs allow for easier cleaning and self draining with improved efficiency

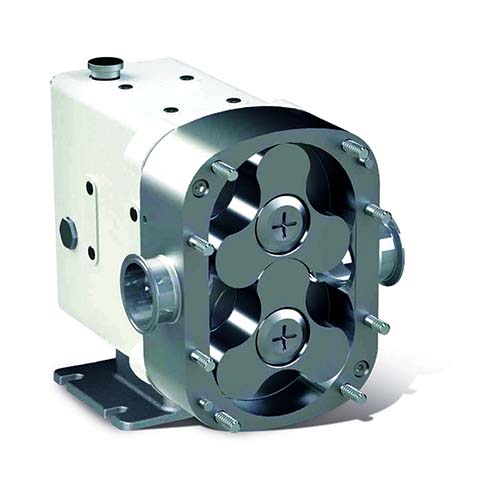

Classic + Multilobe

CLEANABILITY

- Modular pump design promotes easy disassembly for COP (Clean Out of Place) & CIP (Clean In Place)

- Casing profile cusps maximize efficiency & draining capability

PERFORMANCE

- Timed, non-contacting rotors minimize shear while providing extended run-dry capability

- Helical timing gears provide high torque & quieter operation for extended pump life

- Tapered roller bearings provide higher operating speeds & better discharge pressures

EASE OF MAINTENANCE

- Removable foot for easier placement

- Classic RLP design

RTP

CLEANABILITY

- The simple design behind the rotor makes strip cleaning easy and fast

- Choose the cleaning process that fits your needs: COP (Clean Out of Place) or CIP (Clean In Place)

EASE OF MAINTENANCE

- Innovative front loading seal design enables quick inspection and easy servicing

- Sealed gearcase with long-life lubrication eliminates oil inspection and filling

- Easy to service design requires no special tools for disassembly and eliminates need for end clearance adjustments

PERFORMANCE

- Easily handles higher viscosity liquids with improved pressure capabilities for faster unloading

- Excellent displacement/weight ratios, meaning more in the tank & less in the cabinet

- Precision helical gears, rotors & shaft design, with optimized bearing position, minimize overhung load – extending seal & bearing life